Dust Extraction Solutions For Grinding Machines

Dust Extraction Solutions For Grinding Machines Specification

- Scrubber Type

- Cartridge Type- Dry

- Orientation

- Horizontal

- Efficiency

- 99.9 % up to 0.5 Microns and above Particle size

- Usage & Applications

- Dust Collection For grinding fumes and dust collection.

- Product Type

- Dust Collection

- Material

- Mild Steel 3 MM THK. With necessary Structural support

- Noise Level

- 80 db

- Capacity

- 6000 CMH m3/hr

- Voltage

- 230 Volt (v)

- Dimension (L*W*H)

- 2425x1990x3115 Millimeter (mm)

- Warranty

- 12 Months

Dust Extraction Solutions For Grinding Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Packaging Details

- Wooden Packaging, Plastic Wrapping

- Main Domestic Market

- All India

- Certifications

- ISO:9001:2015, CE

About Dust Extraction Solutions For Grinding Machines

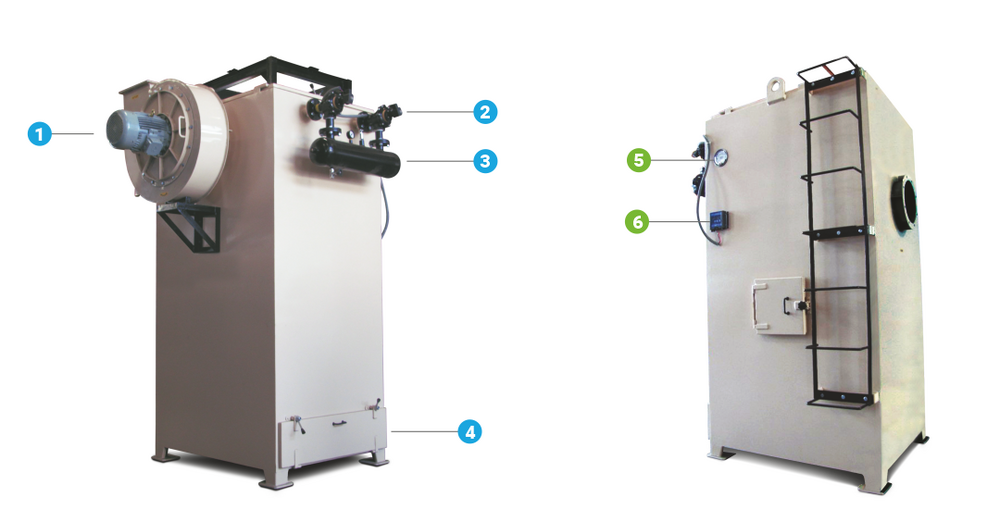

Filter On offers Cartridge type Fumes Extractors / Dust collectors which provide effective solutions for a range of common air pollution problems in manufacturing industries. This is a fully customized range where the equipment is built as per actual requirement of the application & site requirement. Systems from 1000 CMH right up to 60,000 CMH air flow capacities available with various combinations of filter media, filtration area, static pressures, hopper arrangements etc.

Working -

Dusty Air is sucked through the cartridge filters. The dust layer builds on the outer surface of the filters. After preset time, a compressed air jet is blown through the cartridge in reverse direction. Because of this, the dust built on the surface of the filter falls down and gets collected in the dust bin. The dust bin needs to be cleared periodically.

Features & Advantages “

Different sizes and configurations available as per application needs.

Applications -

1. Grinding dust collection

2. Plasma Cutting Fumes Extraction

3. Laser Cutting Fumes Extraction

4. Welding Fumes Extraction

5. Metal “ melting Furnace Fumes Extraction

6. Saw dust collection in woodworking industry

- Application - Industrial

- Condition - New

- Standard - First Class

- Operation - Semi Automaticï

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Fume Extraction System Category

Fume Extractor for EDM Machines

Price 75000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 12 Months

Capacity : 1000 CMH m3/hr

Usage & Applications : Fume extraction for EDM machine fumes solutions

Efficiency : 95+/2% down to 0.5micron size particles

Dust Collector for Gauging & Inspection Stations

Price 250000.0 INR / Set

Minimum Order Quantity : 1 Set

Warranty : 12 Months

Capacity : 2000 m3/hr

Usage & Applications : Dust and fume extraction system for gauging application

Efficiency : 99.9 % up to 0.5 Microns and above Particle size

CNC Machining Fumes And Mist Extractions Solutions

Minimum Order Quantity : 1 Unit

Warranty : 12 Months

Capacity : 2000 m3/hr

Usage & Applications : Oil mist extraction solution for CNC machining fumes

Efficiency : 95+/2% down to 0.5micron size particles

Welding Extraction System

Minimum Order Quantity : 1 Unit

Warranty : 12 Months

Capacity : 1000 CMH m3/hr

Usage & Applications : Best Suitable For Welding rotators, Welding stations, small SPMs

Efficiency : 95+/2% down to 0.5micron size particles