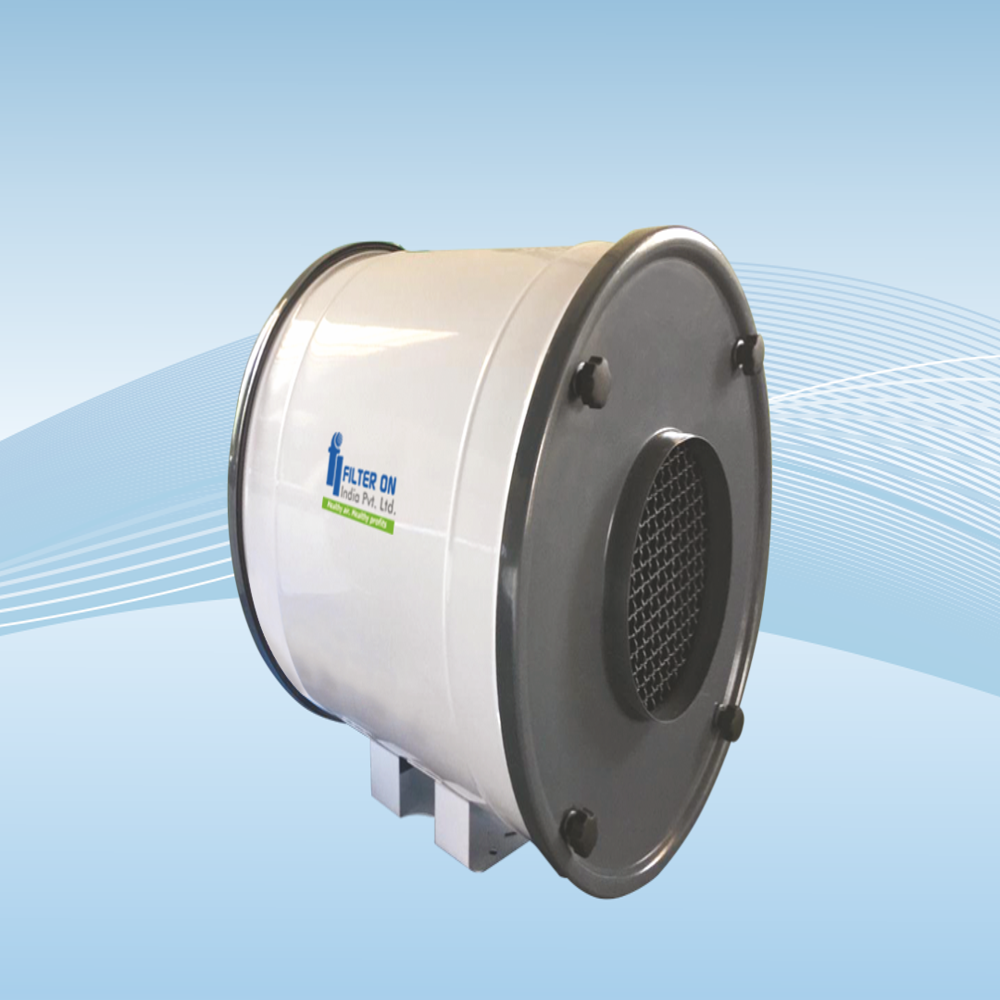

HMC And VMCs Oil Mist Extraction Solutions for CNC Machining Centers

HMC And VMCs Oil Mist Extraction Solutions for CNC Machining Centers Specification

- Usage & Applications

- HMC & VMC mist collector solutions

- Efficiency

- 1 MICRON 98.00% COLLECTION EFFICENCY

- Scrubber Type

- Centrifugal Cartridge Type

- Orientation

- Centrifugal Type

- Product Type

- HMC And VMCs Oil Mist Extraction Solutions for CNC Machining Centers

- Material

- MILD STEEL ALKALINE RESISTANCE COAT

- Noise Level

- 68 db

- Capacity

- 900 CMH m3/hr

- Voltage

- 230 Volt (v)

- Weight

- 40 Kilograms (kg)

- Dimension (L*W*H)

- 475mm OD x 400mm length Millimeter (mm)

- Warranty

- 12 Months

HMC And VMCs Oil Mist Extraction Solutions for CNC Machining Centers Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 30 Days

- Packaging Details

- Wooden Packaging, Plastic Wrapping

- Main Domestic Market

- All India

- Certifications

- ISO:9001:2015, CE

About HMC And VMCs Oil Mist Extraction Solutions for CNC Machining Centers

Filter On India's Centrifugal Mist Collectors are eminently suitable for applications in machining operations which include:

- Machining Centers

- Lathes

- Grinding

These devices are particularly effective for facilities experiencing low to moderate levels of mist.

Applications:

The collectors are not limited to managing Water Soluble Coolants for assorted machinery such as VMC, HMC, CNC lathes, etc., but are also advantageous for component cleaning machines.

We offer four distinct models of the Centrifugal Mist Collectors, with capacities ranging from 400m3/hr to 2100 m3/hr, to wit:

C7

C21

C29

C35

Operational Methodology:

The contaminated air, saturated with mist, is drawn into the apparatus through a high-velocity rotor. The centrifugal force generated consolidates minuscule particles, which coalesce into larger droplets of coolant. The aggregated coolant is then directed through a discharge mechanism and reinstated into the CNC machine's system.

Depending on specific parameters such as the application in question, the concentration of mist, and the type of coolant, we apply a diverse array of filters to achieve the utmost efficiency in performance.

Advantages:

- Compact design

- Facile installation process

- Straightforward operation and maintenance routine.

Key Application In Industry:

-

Machining centers (HMC & VMC)

-

Component Cleaning & Washing machines

-

Surface grinders

-

Wire drawing

-

Stamping presses

-

Screw machines and

-

Roll mill operations.

Key Benefits:

-

Improved working environment

-

Improved air quality

-

Reduced mist-related hazards

Price 60000.0 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Fume Extraction System Category

Oil Mist Collector for Sliding Head CNC Machines

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Electrostatic Filtration System

Voltage : 230 Volt (v)

Usage & Applications : Oil Mist Extraction For Sliding Head Machines

Material : MS 16G powder coated in RAL 7035

Oil Mist Collector for CNC 5-Axis Machines, Tool & Cutter Grinders

Price 150000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Electrostatic Filtration System

Voltage : 230 Volt (v)

Usage & Applications : Fume and dust extraction solutions for tool and cutter (5 axis ) grinding application

Material : MS 16G powder coated in RAL 7035

Melting And Heat Treatment Fumes Extraction System

Minimum Order Quantity : 1 Unit

Product Type : Cartridge Type

Voltage : 230 Volt (v)

Usage & Applications : Fume and dust extraction solutions for melting and furnace application

Material : Mild Steel 3 MM THK. With necessary Structural support

Laser And Plasma Cutting Fume Extraction Solutions

Minimum Order Quantity : 1 Unit

Product Type : Laser And Plasma Cutting Fume Extraction Solutions

Voltage : 220240 Volt (v)

Usage & Applications : Laser cutting and plasma cutting applications

Material : Mild Steel 3 MM THK. With necessary Structural support